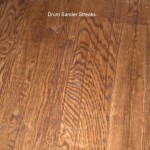

We Recently installed and finished a Wide Plank Hand Scraped White Oak floor in a beautiful home near Danville, AR. The floor was rustic white oak, mixed width 6,7 and 8 inch wide planks. The floor was finished with a Minwax Jacobean color and oil based finish. You can see by the pictures, the floor turned out very nice.